DYCONEX AG

Engineering FAQ's

You will find our frequently asked questions focussing on engineering here.

Profile

Facts & Figures

Engineering

Quality

Publications

Based in Switzerland, DYCONEX AG is one of the world’s leading providers of miniaturized, highly complex and highly reliable solutions in the area of interconnect technology. The company has its seeds in a 1964 founded division within Oerlikon-Contraves and acts as DYCONEX since a management buy-out in 1991. As one of the true pioneers in the industry, DYCONEX has continuously applied the latest technology to derive innovative technologies for various markets.

DYCONEX provides a competitive edge for your business through its high-end interconnect expertise and is an extremely reliable and predictable partner who can deliver products and services with premium quality.

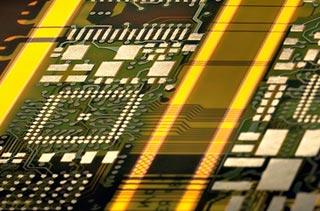

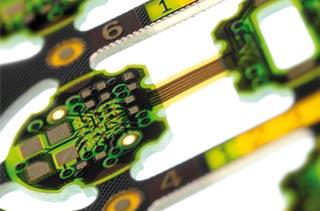

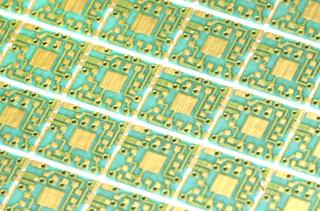

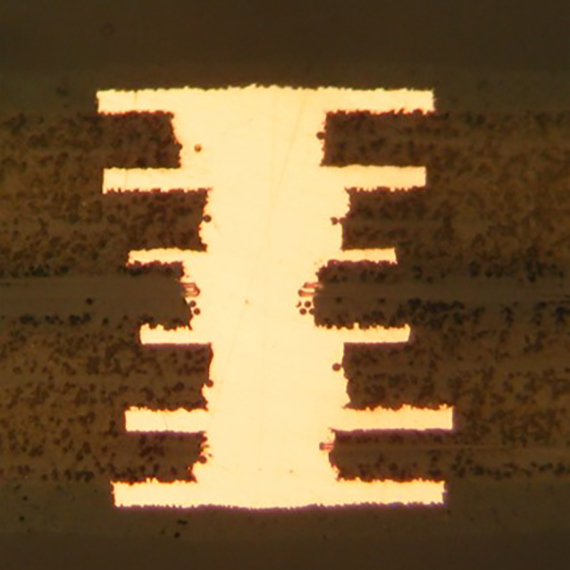

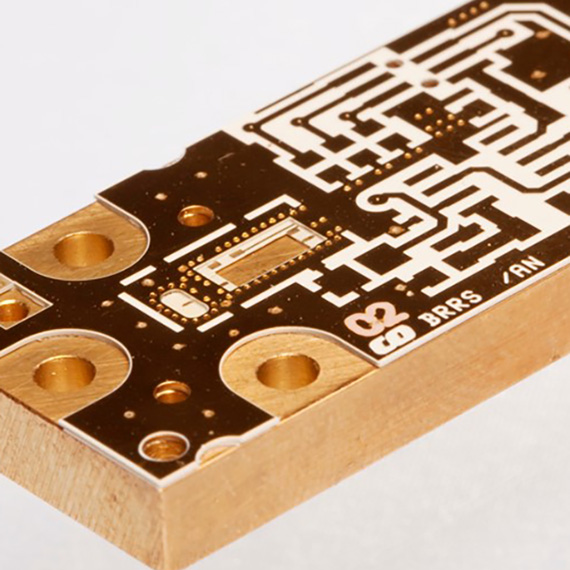

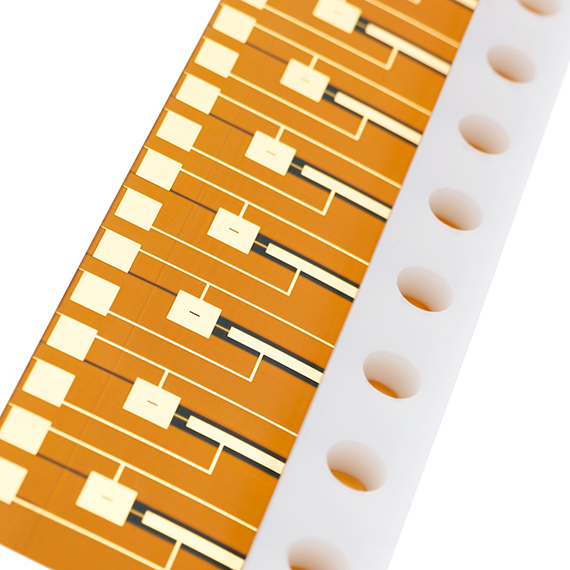

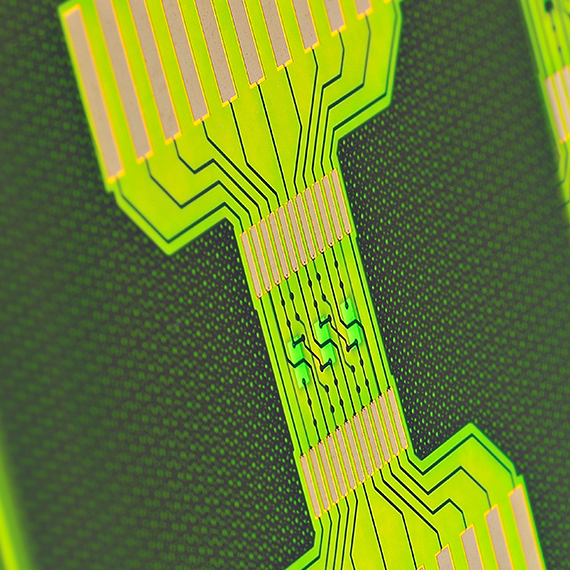

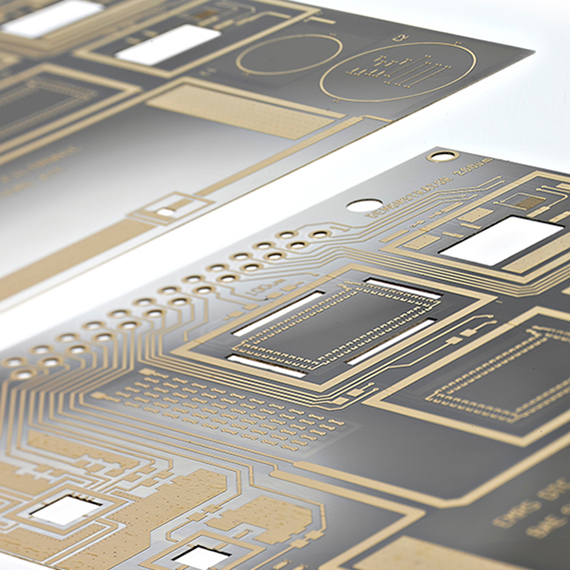

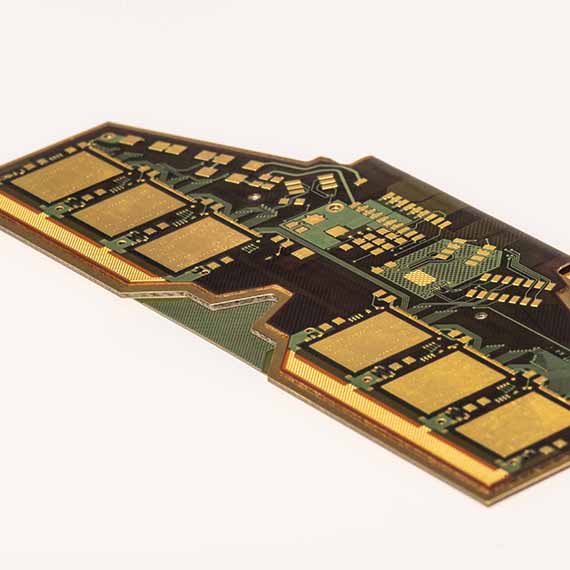

Due to long-term dedication and expertise, DYCONEX has earned a solid reputation for being a technology leader and the partner of choice for providing leading flex, rigid-flex and rigid ultra-HDI/microvia circuit boards, LCP and chip packaging solutions - custom tailored to the corresponding requirements. The company offers all the technological prerequisites needed to implement the most challenging solutions, and among them are ultra-fine structures, ultra-thin base materials, thin film technology, stacked and filled holes, biocompatible materials, embedded components, as well as the latest high performance base materials.

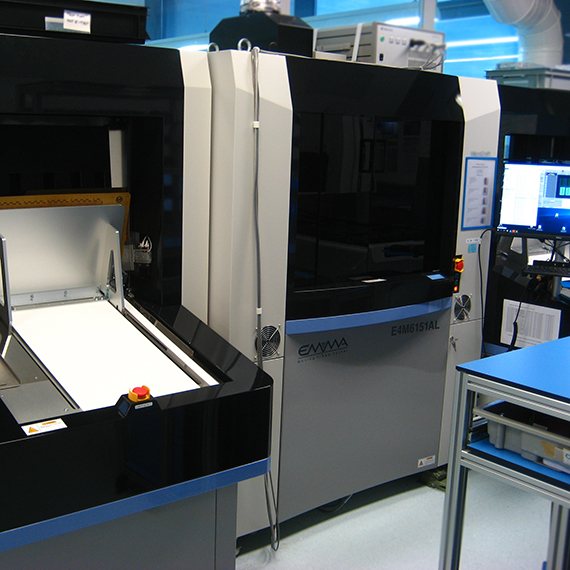

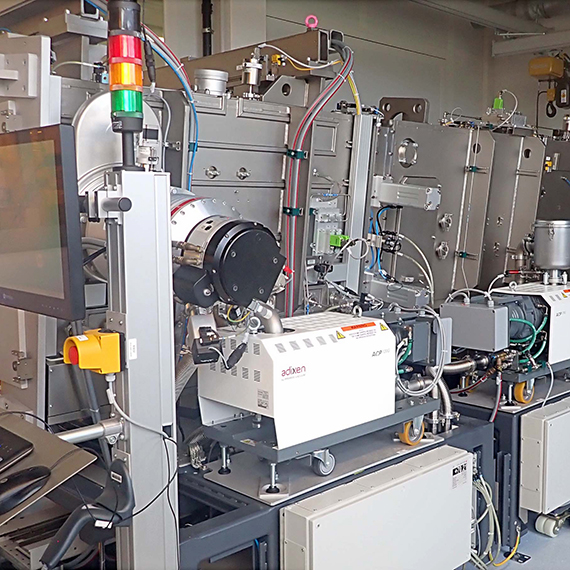

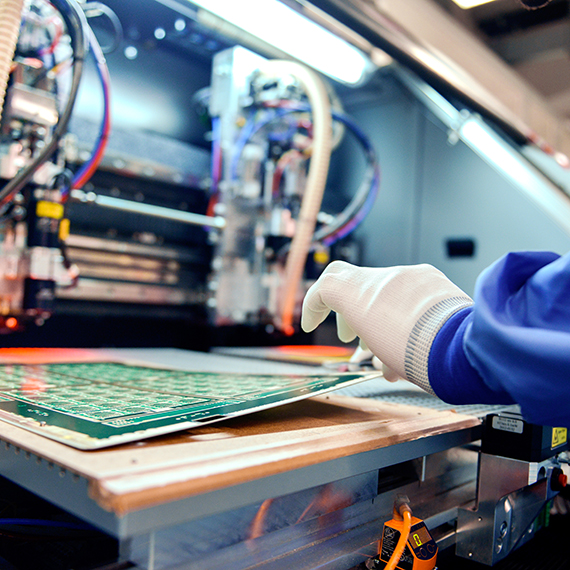

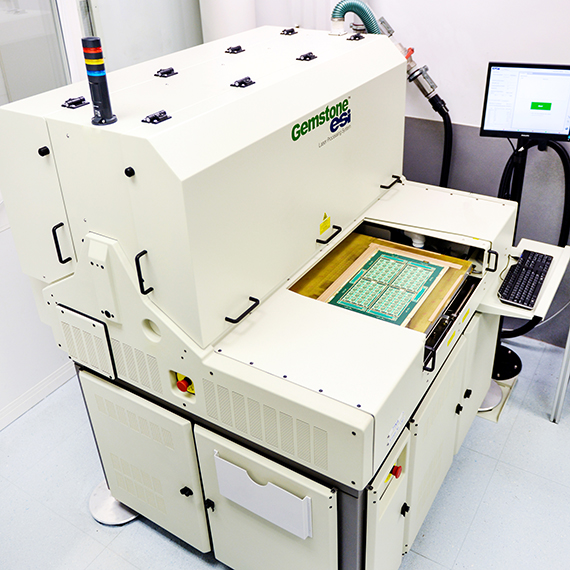

State-of-the-art manufacturing and inspection systems, a high level of automation plus a flexible manufacturing processes allow to produce circuit boards with the highest possible connection density.

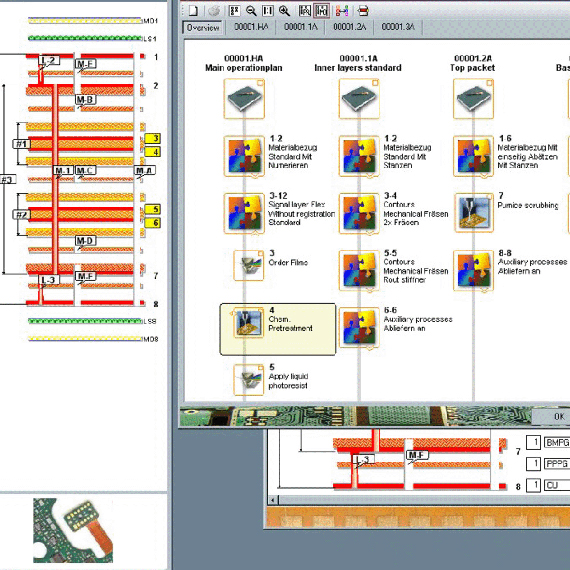

Manufacturing processes at DYCONEX are completely integrated into a manufacturing execution system (MES). Materials and processes are 100 percent traceable. The company is ISO 9001, ISO 13485 and EN 9100 certified.

DYCONEX is located in Bassersdorf, roughly 10 minutes from the Zurich/Kloten airport. The firm has total floor space of more than 6'000 m2, of which 600 m2 are a Class 10'000 cleanroom. The company currently has approximately 190 employees.

|

Experience |

Since 1964 (Management buy-out as DYCONEX in 1991) |

|

Headquarters |

Bassersdorf / Zurich, Switzerland |

|

Business premises |

6'000m2, including 600m2 of clean room |

|

Employees |

>190 |

|

Products |

|

|

Main export markets |

USA, Europe, Asia-Pacific, Australia |

|

Management |

Dr. Hubert Zimmermann, Christian Ahr, Bernhard Schmucki, Christian Beck, Dr. Selçuk Mentese |

|

Quality standards |

|

|

Memberships |

EIPC, FED, IMAPS, IPC, MEPTEC, SMTA, Swiss Aerospace Cluster, SWISS MEDTECH, Switzerland Global Enterprise, ZVEI |

|

Financial rating |

Risk Indicator 1 award by Bisnode Dun & Bradstreet for financial stability and high credit standing

|

DYCONEX AG

Grindelstrasse 40

CH-8303 Bassersdorf

Switzerland

Tel. +41 (43) 266 1100

Fax +41 (43) 266 1101

mail.dyconex(at)mst.com

A comprehensive offering goes beyond producing and delivering PCBs. Close cooperation with our customers from the early R&D phase until the product phase-out ensures the best PCB solution: technically as well as financially. This is why DYCONEX offers comprehensive engineering services that accompany customers throughout the product life cycle.

Design & layout

- Feasibility study support

- Consulting on design for manufacturing (build-ups, materials, test procedures)

- CTE control

- Form factor and weight optimization

- Consulting on design for reliability

- Cost optimization support

- Data conversion to Gerber files

- Technical training and workshops

Production & logistics

- Hand carry

- Express shipments

- Buffer stock

- Consignment stock

- Blister packs

Prototyping

- Engineering support

- Fast prototyping services

- Technological prototyping services

- Wrap-up on first prototype run

Years of experience working in the field of life-sustaining medical devices and high-end industrial projects have led to an uncompromising quality management system. The goal is to assure predictability in the manufacture of high-complexity interconnect solutions.

To meet this challenge, DYCONEX has developed an integrated control and inspection concept (DYCO IC2), allowing to continuously improve the business and production processes.

Quality Tools

The implementation of advanced quality tools and techniques provides accountability and is an essential ingredient in the effort for sustainable improvement.

- 100% traceability for every single PCB

- First article inspection

- 8D reports

- DoE, SPC and MSA

- Six Sigma methodology

- Change management

- IQ/OQ/PQ validation methodology

- CAPA process

- Customized inspection concepts and reports

- Maverick control

Inspection and Test

Enabled through sophisticated equipment and skilled professionals, the company is determined to supply only high-reliability, Swiss quality solutions to their markets.

- 100% electrical testing

- Automated optical inspection

- Automated final inspection

- Micro-section control

- Interconnect stress test (IST)

- Bondability analysis

- Ionic contamination measurement

- X-ray inspection

- FPC bending tests

- Scanning electron microscope

- TMA/DMA material analysis

Approvals and Standards

DYCONEX’ approvals and quality management system demonstrate the ability to provide PCB solutions that consistently meet applicable customer and regulatory requirements.

- ISO 9001, ISO 13485, EN 9100 and ISO 14001 certified

- Manufacturing and testing according to IPC standards and customer-specific requirements

- Certified Six Sigma Black Belts and IPC qualified employees

- RoHS and REACH compliance

Downloads

|

Ultra-thin base materials take PCB miniaturisation to the next level Flexible and rigid ultra-thin base materials enable highly reliable, thinner PCBs Authors: Daniel Schulze |

|

Flexible Substrates for Smart Sensor Applications A novel approach that delivers miniaturized, hermetic, biostable and highly reliable smart sensor modules. Authors: Dr. Eckardt Bihler, Dr. Marc Hauer, Birgit Neubauer |

|

Why Predictability Matters in High-End PCB Manufacturing An advanced approach that delivers predictability, serving as the basis for assuring ongoing reliability. |

|

Noble Metal PCB Manufacturing for Direct Implants The market of active implantable devices requires new strategies in designing and manufacturing the relevant components. |

DYCONEX AG

Grindelstrasse 40

CH-8303 Bassersdorf

Switzerland

Tel. +41 (43) 266 1100

Fax +41 (43) 266 1101

mail.dyconex(at)mst.com

OUR HISTORY

DYCONEX from 1991 to Today

DYCONEX is proud of its 30-year history and consistent development of leadinge-edge innovations. Our commitment to be the world’s leading provider of complex, ultra dense and highly reliable interconnect solutions has made us what we are today.

DYCONEX AG

Grindelstrasse 40

CH-8303 Bassersdorf

Switzerland

Tel. +41 (43) 266 1100

Fax +41 (43) 266 1101

mail.dyconex(at)mst.com