Enabling Technologies

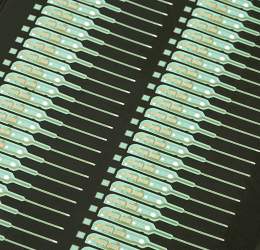

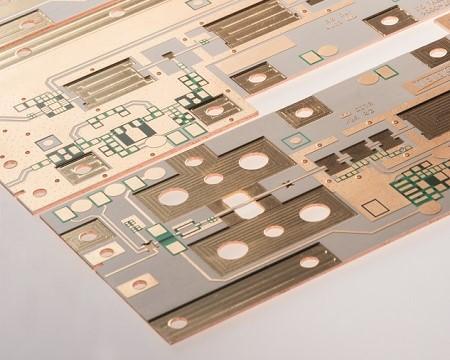

Miniaturisation

With ever-more functionalities integrated into electronic devices and the ubiquitous need for mobility miniaturization has become a decisive factor in most applications. DYCONEX provides enabling technologies for your miniaturization of electronics interconnects.

- Ultra-thin base materials

- Ultra-fine line technology

- Microvias, via stacking and filled vias

- LDI technology

- Component embedding

- Advanced registration concepts

- Thin film technology

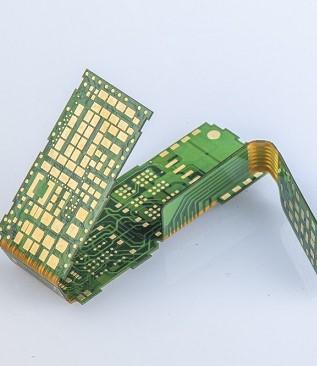

Functionality

With Industry 4.0, Big Data, Internet of things and many more on-going trends demand for increased functionality of electronic components, devices and systems. DYCONEX provides materials and technologies for densely interconnected functionality in your electronic package.

- Various conductor metals

- High performance base materials

- Foldable systems

- Embedding of active and passive components

- 3D shaping of interconnect devices

- Stretchable PCBs

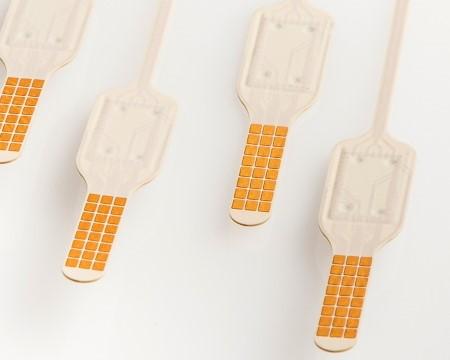

Biocompatibility

Wherever electronics gets in contact with living tissues, be it implants, prosthetics or wearables, harmonious biological functioning has to be supported and adverse reaction to be avoided. As a supplier into medical applications for decades, DYCONEX has a well proven understanding of biocompatibility of electronics products.

- Biocompatible base materials such as LCP or PI

- ISO 10993-1:2009 certified (in vitro cytotoxicity)

- Noble metal plating

- For short term and long-term implants

- Embedding of active and passive components

- Full module encapsulation by LCP

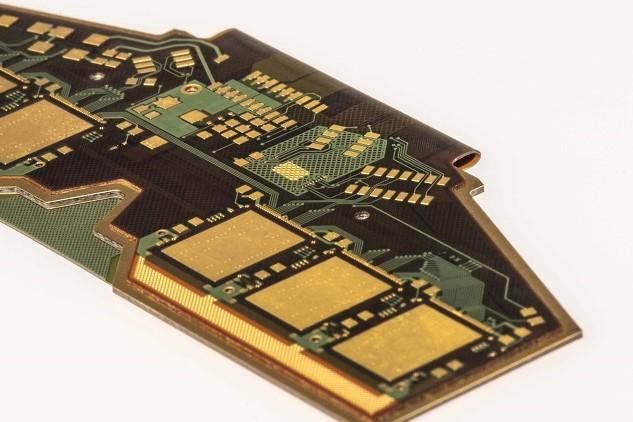

Thermal management

Miniaturisation and increased functionality in electronic devices lead to a higher power dissipation. Thermal performance of the PCB thus has become a critical parameter to maintain system reliability. DYCONEX supports the optimization of board design, deploys materials with advanced thermal performance and uses innovative build-up concepts for an efficient thermal management on your PCB.

- Wrap-around technology

- Metal sheets as backpanels

- Metal inserts and cores as heat sink

- Thermal vias for heat dissipation

- Copper filled microvias for heat removal

- CIC technology to control thermal expansion

Thermal management

Increasing desire for connectivity, mobility, security and on-going changes in our working environment drive the convergence of localization, positioning and communication technologies. RF applications are ubiquitous in industrial medical and commercial applications. DYCONEX offers design support, materials and processes to support this evolution.

- LCP base material

- Advanced rigid multilayer material

- High Tg, low CTE and high dielectric strength

- Impedance control by design

- Very tight process tolerances

- Ultra-low-profile copper

- Anylayer build-ups for high frequency

- Chip cavities for short wire bonds

Reliability & Predictability

As a class III medical grade supplier Dyconex provides design, engineering, manufacturing and quality assurance services of proven quality and reliability also for applications outside medical.

- Design for highest reliability

- Digital factory with full traceability

- Integrated control and inspection concept

- Two-stage approach to data processing

- IST testing and analysis

- Maverick control