LTCC - Low Temperature Co-fired Ceramic

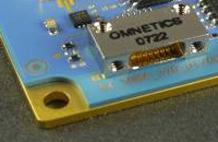

LTCC (Low Temperature Co-fired Ceramic) is a multilayer capable substrate technology offering excellent RF and microwave performance characteristics. Its low sintering temperature (approximately 900°C) allows co-firing with highly conductive metals such as silver and gold. The excellent mechanical and electrical properties of LTCC substrates, combined with the ability to embed passive components, offer superior RF performance and device miniaturization for high frequency applications.

About LTCC

LTCC features

LTCC properties

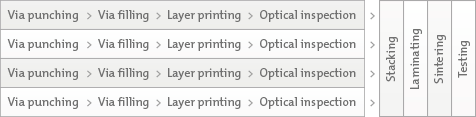

LTCC process flow

The multilayer technology allows for the parallel stacking of up to more than 20 layers.

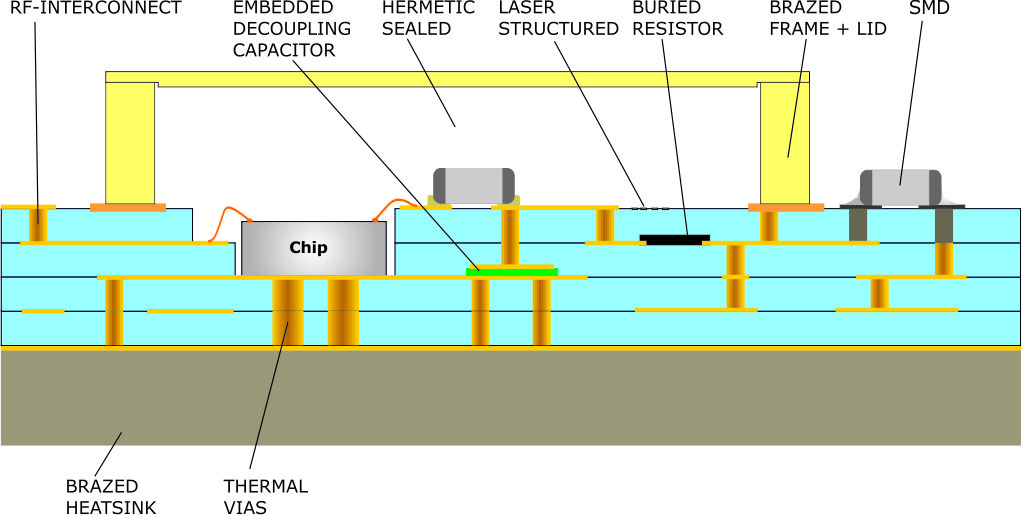

The excellent mechanical and electrical properties of LTCC substrates, combined with the ability to embed passive components and to apply fine line patterning, offer superior RF performance and device miniaturization for high-frequency applications.

Further features like the application of heat sinks, frames and nail head pins by brazing allow for hermetic and highly complex packages.

Quality performance testing and assurance

In-process and final inspection procedures include:

- Automated optical inspection using a MIDAS Vision AOI system

- Electrical inspection using an ATG flying probe test system

- Visual inspection

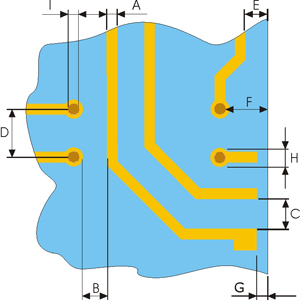

LTCC dimensional capabilities

|

Index |

Description |

Specification |

|

A |

Line width |

80 µm |

|

B |

Line to via coverpad spacing |

100 µm |

|

C |

Line spacing |

80 µm |

|

D |

Via pitch |

300 µm (*, #) |

|

E |

Line to edge spacing |

200 µm |

|

F |

Via to edge spacing |

300 µm |

|

G |

Pad to edge spacing |

200 µm |

|

H |

Via coverpad |

I + 50 µm |

|

I |

Via diameter |

≥ 100 µm |

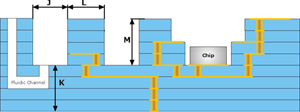

Cavities and windows

|

Index |

Description |

Specification |

|

J |

Cavity width/length |

≥ 800 µm (#)

|

|

K |

Cavity bottom thickness |

2 layers |

|

L |

Distance between cavities # Smaller sizes on request |

≥ 2 mm (#)

|

|

M |

Cavity depth |

Design related |

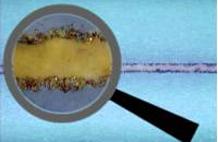

Integrated passive components

Capacitors

- Embedded

- Multilayer

- Up to 20 pF/mm2

Inductors

- Planar

- 3D

Resistors

- Trimmable post-fire (7 decades)

- Buried co-fire

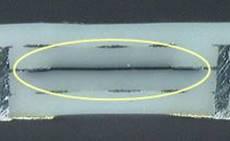

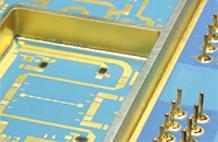

Brazing operations

Metal plates

- Housing

- Heatsinks / thermal management

Frames

- Hermetic packages

- Shielding

Pins

- Connectors

- Board connection

Mechanical processing

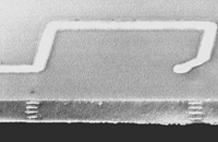

Laser cutting / scribing in green state

- Accuracy: ± 0.130 mm

Machining after firing

- Accuracy: ± 0.130 mm

RF performance

- Good impedance control

- Low to medium k-values

- High conductive metals

- Low dielectric losses up to 120 GHz

Electrical properties of microwave materials

|

Name |

|

LTCC |

LTCC |

LTCC |

Thick film on |

|

Type |

|

Dielectric layer |

Dielectric layer |

Dielectric layer |

Dielectric substrate |

|

Thickness |

µm |

(40), 98, 135, 204 |

98, 196 |

88, 135, 176 |

250, 380, 500, 630,1000 |

|

Electrical properties |

|

|

|

|

|

|

Dielectric Constant |

10 GHz |

7.5 |

7.1 |

7.2 |

9.8 |

|

Dissipation Factor (tan δ) |

10 GHz |

0.006 |

0.001 |

0.002 |

0.0006 |

|

Dielectric Strength |

kV/mil |

>1 |

>1 |

>1 |

>1 |

|

Mechanical properties |

|

|

|

|

|

|

Youngs Modulus |

GPa |

120 |

145 |

113 |

340 |

|

Felxural Strength |

MPA |

320 |

230 |

275 |

400 |

|

Fired Density |

g/cm³ |

3.1 |

3.1 |

3.1 |

3.8 |

|

Thermal properties |

|

|

|

|

|

|

CTE |

ppm/K |

5.8 |

4.4 |

5.8 |

6.8 |

|

Typ. Thermal Cunductivity |

W/mK |

4 |

4.6 |

>3 |

24 |