Image

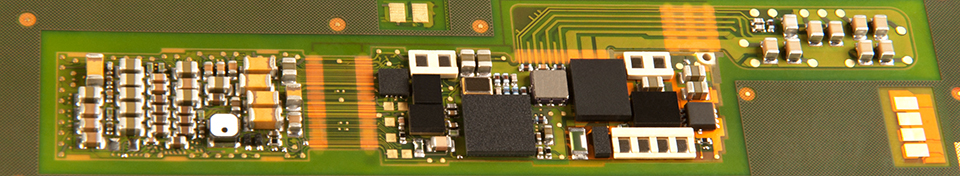

Advanced assembly

A wide range of assembly equipment and inspection technologies enable us to assemble an extensive variety of components (like SMD, BGA, LGA, CSP, flip chips or bare dies) on any board material for the production of complex, miniaturised electronic modules.

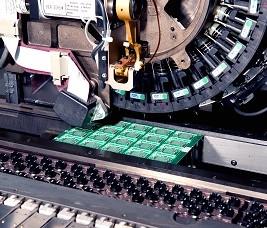

Surface Mount Technology (SMT)

- Fully automated SMD assembly

- MES controlled

- Plasma and IPA cleaning available

- 01005 components up to 85 x 85 mm2

Die attach technologies

- Gluing by epoxy printing, epoxy dispensing, pre-forms and stamping

- Soldering by solder printing, solder dispensing and pre-forms

- High precision die bonder can pick from wafers, waffle packs or gel-packs

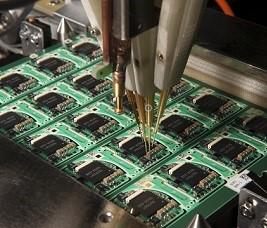

Wire bonding

- Ultrasonic bonding for Al thin/thick wires

- Thermosonic wedge/wedge bonding for Au thin and Au cold wires

- Thermosonic ball/wedge bonding for Au thin wires

- Special wires

Die protection / encapsulation

- Glop top (temperature or UV curing)

- Underfill

- Junction coating

- Transfer moulding

- Soldering or gluing for covers and lids

Design and test services

- Component design and selection

- Incoming inspection and test

- 3D mechanical and electrical design

- Supply chain management

- Automated in-circuit and functional test

- Full MES control, digital factory

- Single piece traceability